CVD Graphene Transfer

General Graphene has developed efficient processes for rapidly transferring monolayer large-area graphene films onto various customer substrates, components, and devices.

Our transfer methods ensure seamless integration of our high-quality chemical vapor deposition (CVD) graphene materials onto more surfaces than anyone else in the world today.

Wet-Transfer

The industry-standard wet transfer method starts by generating CVD graphene on a metal catalyst foil. The catalyst substrate is chemically etched away to isolate the graphene sheet, making it ready for transfer onto a target surface. Wet transfer is a robust method for transferring high-quality graphene films onto substrates such as silicon wafers and PET. However, this technique is performed at a batch-scale and leaves no potential for catalyst reuse – thereby limiting scalability and affordability relative to our roll-to-roll transfer route.

Wet-Transfer

The industry-standard wet transfer method starts by generating CVD graphene on a metal catalyst foil. The catalyst substrate is chemically etched away to isolate the graphene sheet, making it ready for transfer onto a target surface. Wet transfer is a robust method for transferring high-quality graphene films onto substrates such as silicon wafers and PET. However, this technique is performed at a batch-scale and leaves no potential for catalyst reuse – thereby limiting scalability and affordability relative to our roll-to-roll transfer route.

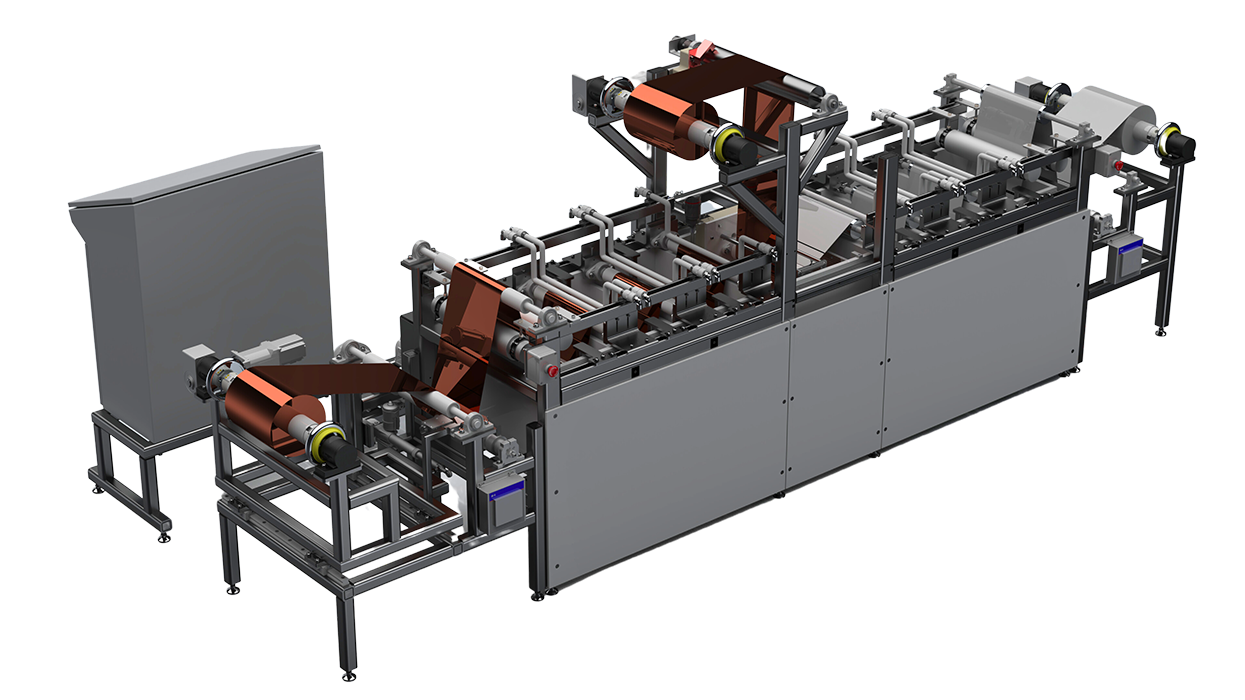

Roll-to-Roll Transfer

Roll-to-roll graphene transfer has been the goal for several monolayer graphene producers, but most have found the technique difficult to master due to the induction of defects when large-area graphene transfers are performed. The first step of our roll-to-roll transfer procedure takes place in our inline polymer coating system, where we apply thin polymer spray coatings which are cured and laminated with a structural backer.

The polymer-graphene-copper heterostructure is then fed into our Roll-to-Roll Transfer system, where the graphene-on-polymer is separated from the catalyst material’s surface to facilitate catalyst recollection and reuse. The resulting graphene-on-polymer output contains minimal structural defects relative to other traditional and roll-to-roll transfer techniques.

Roll-to-Roll Transfer

Roll-to-roll graphene transfer has been the goal for several monolayer graphene producers, but most have found the technique difficult to master due to the induction of defects when large-area graphene transfers are performed. The first step of our roll-to-roll transfer procedure takes place in our inline polymer coating system, where we apply thin polymer spray coatings which are cured and laminated with a structural backer.

The polymer-graphene-copper heterostructure is then fed into our Roll-to-Roll Transfer system, where the graphene-on-polymer is separated from the catalyst material’s surface to facilitate catalyst recollection and reuse. The resulting graphene-on-polymer output contains minimal structural defects relative to other traditional and roll-to-roll transfer techniques.

The ability to reuse the copper foil catalyst delivers significant cost reductions in monolayer graphene manufacturing – thereby accelerating monolayer graphene’s journey towards commercialization.