Our CVD Technology

Chemical vapor deposition (CVD) is one of the leading bottom-up methods to produce graphene and other 2D materials. However traditional CVD systems struggle to yield graphene at reproducible qualities, are typically operated under vacuum conditions, are energy intensive, and expensive.

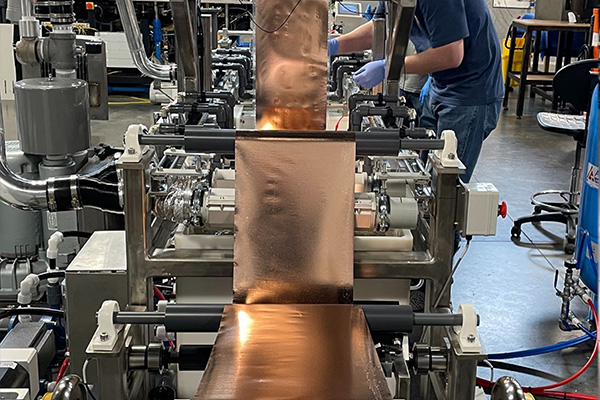

Our roll-to-roll CVD technology breaks the status quo by being one of the world’s first systems capable of industrial-scale CVD graphene synthesis.

Scaling CVD Graphene Manufacturing

Our belief was fundamentally centered on the “chicken and egg” problem – graphene can do wonderful things, but it won’t matter until graphene can be made –

In mass volumes

At affordable price points

At reproducible tailorable qualities that meet application demands

Our innovative approach led to the creation of a prototype in 2017 that demonstrated the first-ever successful synthesis of CVD graphene films under atmospheric conditions and a proof-of-concept manufacturing line in 2018 that validated the scalable production of CVD graphene films under atmospheric conditions.

GG 3.0, the third generation of our CVD graphene production technology, came online in late 2021 and is capable of producing between 65,000 and 100,000 sq. meters of roll-to-roll CVD graphene annually at a direct production cost between two to three orders of magnitude lower than the market, and at reproducible tailorable qualities across an array of applications.

Discover our groundbreaking technology across two key areas:

Production

Dive into the details of our patented proprietary CVD process and learn more about the unique techniques used by our team to deliver CVD graphene materials optimized for specific customer applications.

Transfer

Our expertise in wet-transfer and roll-to-roll transfer methods enables seamless integration of CVD graphene onto a wide range of substrates across various applications.