Schematic of graphene field-effect transistor (GFET) after functionalization with receptors (top) and when interacting with analytes (bottom).

What Makes CVD Graphene Suitable for Sensors?

CVD graphene is an atomically thin layer of carbon atoms arranged in a hexagonal lattice structure. As a two-dimensional carbon nanomaterial, CVD graphene possesses a unique set of properties that allow it to serve as an enabling material across a broad spectrum of industries and applications. It is no coincidence that carbon and silicon are neighbors on the periodic table, as CVD graphene’s role as an enabling material can be compared to that of silicon.

CVD graphene finds its reputation as an enabling material in applications such as sensors. Being a two-dimensional atomically thin nanomaterial, CVD graphene possesses an extremely high surface area to volume ratio, which is beneficial for target agents and stimuli to interact with the CVD graphene surface. Furthermore, CVD graphene is a semi-metal with high field-effect mobility which allows for a high degree of sensitivity in response to external stimuli or agents.

CVD Graphene Strain Sensors

The operating principle of strain sensors relies primarily on the change in the electrical properties of the strain-sensing element in response to applied pressure or force. A change in the electrical resistivity of the strain-sensing element in response to an applied mechanical strain is known as the piezoresistive effect. Strain sensors are among the most used sensing elements globally and are applied across a wide spectrum of industries and applications.

CVD graphene possesses high stretchability (Young’s Modulus of ~1 TPa ) for strain-sensing applications. The inherent stretchability of CVD graphene determines its tolerance to forces applied because of bending, compressing, or stretching the material. CVD graphene also possesses a linear change of resistance versus strain which also makes it a good candidate for piezoresistive strain sensing applications [1].

Strain sensing is used in wearable devices and physical sensors such as accelerometers to measure acceleration [1]. The use of wearable devices is widespread across healthcare monitoring applications. On the other hand, physical sensors can be used for stability control and crash detection in automotive applications, navigation systems, robotics, and military applications.

CVD Graphene Gas Sensors

Chemiresistors are the most common gas sensors which detect the presence of gaseous molecules by changing the electrical resistance of the sensing layers in response to the gaseous molecules being adsorbed. Field-effect transistors (FETs) are also used for gas sensors, with their performance being dependent on their on-off current ratio [2]. CVD graphene gas sensors operate by changing the surface electrical conductivity in response to the adsorption of the target gaseous molecule, thereby following a similar operating principle to chemiresistors [2].

Compared to conventional gas sensors, CVD graphene gas sensors can operate at a very low power. This is because of CVD graphene’s high electron mobility and low noise level, which allows the sensors to operate at low voltages. As a result, CVD graphene gas sensors can be integrated with low-power electronic systems, making them ideal for portable and remote sensing applications.

Furthermore, CVD graphene gas sensors can detect changes in gas concentration rapidly, thus giving them a fast response time. The high surface area to volume ratio of CVD graphene enables gas molecules to diffuse quickly and interact with the CVD graphene surface, leading to a fast response time. This is particularly important in applications such as air quality monitoring, where accurate instantaneous measurements are required. CVD graphene gas sensors have been able to detect gases such as NO2, CO, NH3, and CH4 with high sensitivity and selectivity.

CVD Graphene Biosensors

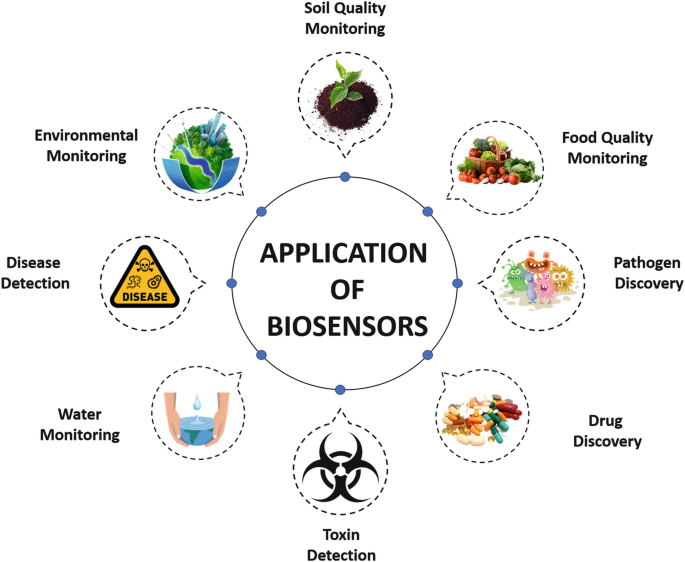

Applications of CVD graphene biosensors

CVD graphene is biocompatible, meaning it will not interfere with biological systems and will remain inert when interacting with biological agents. Furthermore, CVD graphene can be easily functionalized by adding specific functionalization groups to its surface, which subsequently interact selectively with biological targets. CVD graphene’s functionalization potential is almost limitless, which paves the way for the development of CVD graphene biosensors that can be used to detect a variety of biological agents, toxins, and molecules. Additionally, CVD graphene biosensor platforms can also offer multiplexing capabilities while maintaining their high sensitivity. The need for parallel testing and large sample volumes of target analytes is highly reduced due to the multiplexing capabilities and high sensitivity of CVD graphene biosensors.

CVD graphene is typically used in field-effect transistors (FETs) for biosensor applications. The FET biosensor consists of a CVD graphene surface acting as the channel and three electrodes [3]. The CVD graphene channel is typically functionalized with a biomolecular receptor – antibodies, aptamers, enzymes, DNA, or other biorecognition elements – to convert the FET into a fully functioning biosensor [3].

CVD graphene biosensor platforms can detect a variety of analytes – DNA, RNA, glucose, antigens, viruses (COVID-19, influenza, and more). Several companies are currently using graphene for FET-based biosensors. For example, Cardea Bio’s BPU™, a graphene-based biosensor, has successfully reduced the time needed to complete isothermal titration calorimetry (ITC) measurements from 14 days to 1 day. This represents a breakthrough in the drug discovery field, as ITC is an extremely important tool used in the design and development of new pharmaceutical drugs.

CVD graphene biosensors are the missing link in the effort to digitize the medical and biopharmaceutical industries.

Scaling and Commercializing CVD Graphene Sensors

The sensors discussed above represent a small portion of the overall sensor market that CVD graphene can help enable. CVD graphene’s near-limitless functionalization potential, combined with its unique set of properties, enables it to be applied across various types of sensors. Other sensors that can be developed with CVD graphene include:

- Temperature Sensors – Due to its high thermal conductivity and temperature-dependent resistance, CVD graphene can be utilized in temperature sensors to measure temperature changes with high accuracy and sensitivity for industrial process control, environmental monitoring, and medical applications.

- Humidity Sensors – Due to the rapid change in surface electrical resistance in response to humidity changes and its large surface area to volume ratio, CVD graphene can also be utilized in humidity sensors with high accuracy and sensitivity for agriculture, food processing, and HVAC system applications.

- Pressure Sensors – Due to the changes in surface electrical resistance caused by pressure-induced deformation, CVD graphene can be used in pressure sensors with high accuracy and sensitivity for robotics, medical devices, and aerospace applications.

- Magnetic Field Sensors – CVD graphene’s high field-effect mobility and low noise level make it an excellent material for magnetic field sensors. Upon interacting with magnetic fields, the electrical properties of CVD graphene change, which enables the development of magnetic field sensors with high sensitivity and selectivity for medical imaging and navigation applications.

- Optical Sensors – CVD graphene possesses excellent optical properties such as high transmittance, low reflectance, and high absorption which can be harnessed to develop optical sensors. Upon interacting with light, the electrical resistance of CVD graphene changes which enables the development of optical sensors with high sensitivity and selectivity for environmental monitoring and food safety applications.

General Graphene possesses the capability to seamlessly grow and apply graphene on a variety of polymers which are the most cost-effective substrate for several sensor applications. With a roll-to-roll chemical vapor deposition (CVD) production process capable of producing industrial-scale CVD graphene cost-effectively in mass volumes and at a reproducible high quality, General Graphene is fully equipped to deliver CVD graphene materials tailored for your sensor application in mass volumes and at affordable price-points.

Contact us at info@generalgraphenecorp.com to learn more about how we can help scale your CVD graphene sensor application.

References

[1] Yapici, M.K. (2022, February 01). Graphene in Strain Sensing Applications.

In Encyclopedia. https://encyclopedia.pub/entry/19056

[2] Yuan, W., & Shi, G. (2013). Graphene-based gas sensors.

Journal of Materials Chemistry A, 1(35), 10078-10091.

[3] Andronescu, C., & Schuhmann, W. (2017). Graphene-based field effect transistors as biosensors. Current Opinion in Electrochemistry, 3(1), 11-17.